For more than 20 years VBR Turbine Partners are independent maintenance experts for GE LM aeroderivative gas turbines. Our specialized maintenance engineers have high standards when it comes to the right tooling to perform their high-quality professional work. To support them in doing their outstanding work for our customers VBR has developed dedicated tooling like LM2500(+) and LM6000 maintenance dollies, engine transport containers, lifting beams, hot section exchange tooling and dedicated mechanical and controls & instrumentation tool cases.

The benefits of dedicated VBR tooling

| High standard tooling; |

| Optimized tooling designed through years of field experience |

Tooling; tailor made for gas turbines

VBR tailor-made LM maintenance tools are also available to our customers to enhance the capabilities of their on-site maintenance staff.

All VBR engineered LM maintenance tooling is locally manufactured in Europe and contains multiple improvements. All VBR LM tooling enhancements are derived from our long-term on-site expertise and experience in maintaining LM2500(+) and LM6000 gas turbines.

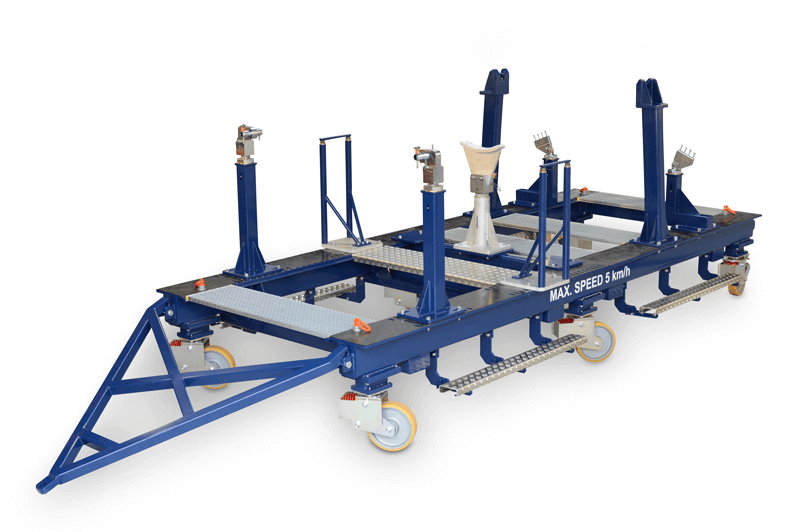

LM6000 maintenance dolly

The most versatile LM6000 (PA-PH) maintenance dolly with many practical improvements.

- Foldable running boards;

- 6 wheel design;

- Better wheels and suspension;

- Better lock up system to adjust the wheels;

- Triangle useable for both sides for easy towing;

- Higher design for work underneath the engine;

- For all versions of the LM6000.

LM2500(+) maintenance dolly

The most versatile LM2500 (+) maintenance dolly with many practical improvements.

- Applicable for LM2500 and LM2500+ versions;

- Can be used as stand alone gas turbine, gas generator or power turbine dolly;

- Can be used as transport or maintenance dolly;

- Secure transport through TMF aft flange support (thick and thin flange);

- Support brackets for DLE manifold included.

High Pressure Turbine Rotor – Vertical stand

This tool is used to store the HPT rotor assembly during a hot section exchange or major overhaul.

Dedicated mechanical tool case

Dedicated mechanical tool case for all LM2500 (+, G4), LM6000 (PA-PH) and LM1600 engines.

Interested in renting LM maintenance tooling?

Did you know that we also rent out tooling? Please contact us for more information. We look forward to provide you with the best available answers and solutions.

VBR-2500-044

Fixture, Lift – Gas Generator/ Gasturbine

Applicable for all LM2500 and LM2500+ versions.

LM2500, LM2500+DLE, SAC, GG, or GT (6 pack).

Interested in LM maintenance tooling?

We look forward to provide you with the best available answers and solutions.

Tooling list

| Partnumber | Description and link to productpage |

|---|---|

| 1C5937G01 | Gage Concentricity No.5 Bearing Inner Ring, Vertical |

| 1C6899G01 | Puller, No. 5R Bearing Inner Ring |

| 1C6905G01 | Clamping Set, O-Ring Installation |

| 1C6952P01 | Wrench, Spanner – Oil Tube High Pressure Turbine Rotor |

| 1C6953G02 | Puller, Oil Tube No. 5 Bearing |

| 1C8069G04 | Fixture Lift – High Pressure Turbine Rotor – Horizontal |

| 1C9428G01 | Wrench, VSV locknut torque break |

| 2C6001G01 | Wrench, No 3R Bearing Race Spanner Nut |

| 2C6063G01 | Puller, Retainer Ring – No. 5 Bearing |

| 2C6066G03 | Fixture, Lift Combustion Liner, Horizontal |

| 2C6196P01 | Pusher, inner-race No.5 bearing |

| 2C6299P28 | Puller Guide |

| 2C6341G02 | Wrench, Spline, Direct Drive |

| VBR-2500-044 | Fixture, Lift – Gas Generator/ Gasturbine |

| 1C8324P02 | Holder Set, Variable Stator Vanes |

| 1C8324P03 | Holder Set, Variable Stator Vanes |

| 1C6856G01 | Wrench, Spanner Nut, No.6 Bearing |

| 1C8351G01 | Fixture, Lift Turbine Mid Frame |

#tools #tooling #liftingbeam