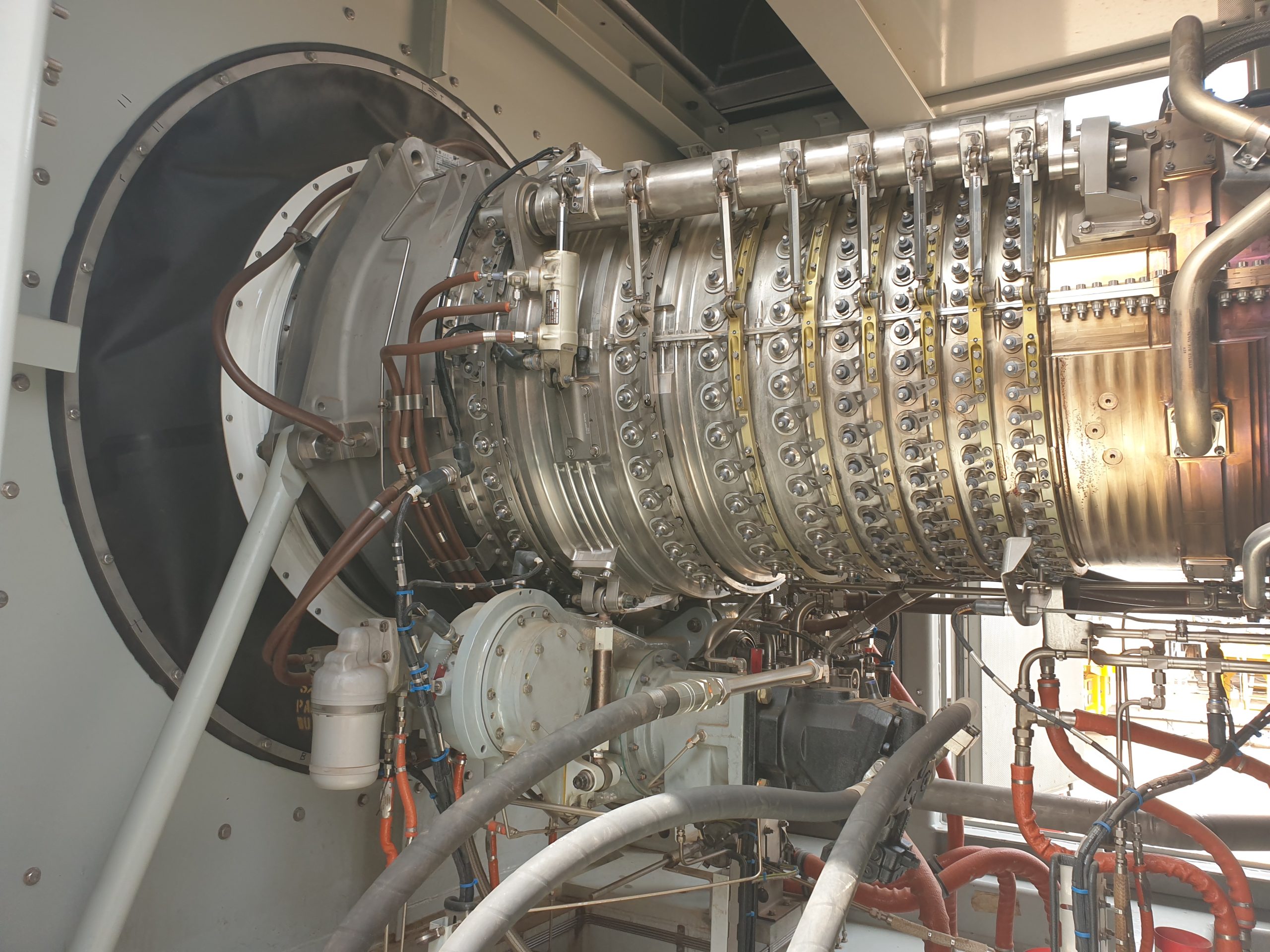

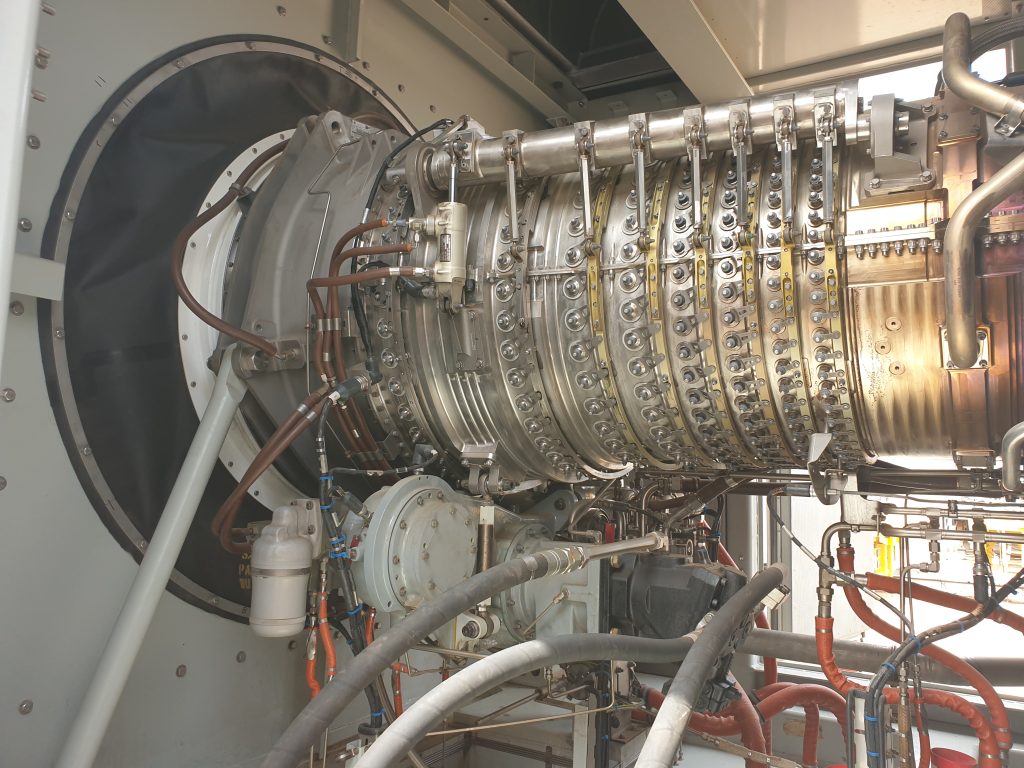

The LM2500 gas turbine and the TM2500 engine

The LM2500 turbine and its related engine, TM2500, play a vital role in delivering reliable energy in remote and hard-to-reach locations.

The gas turbine is mounted on a trailer, making it easy to transport and quickly deploy where needed. This makes it an ideal solution for emergency power and temporary energy projects.

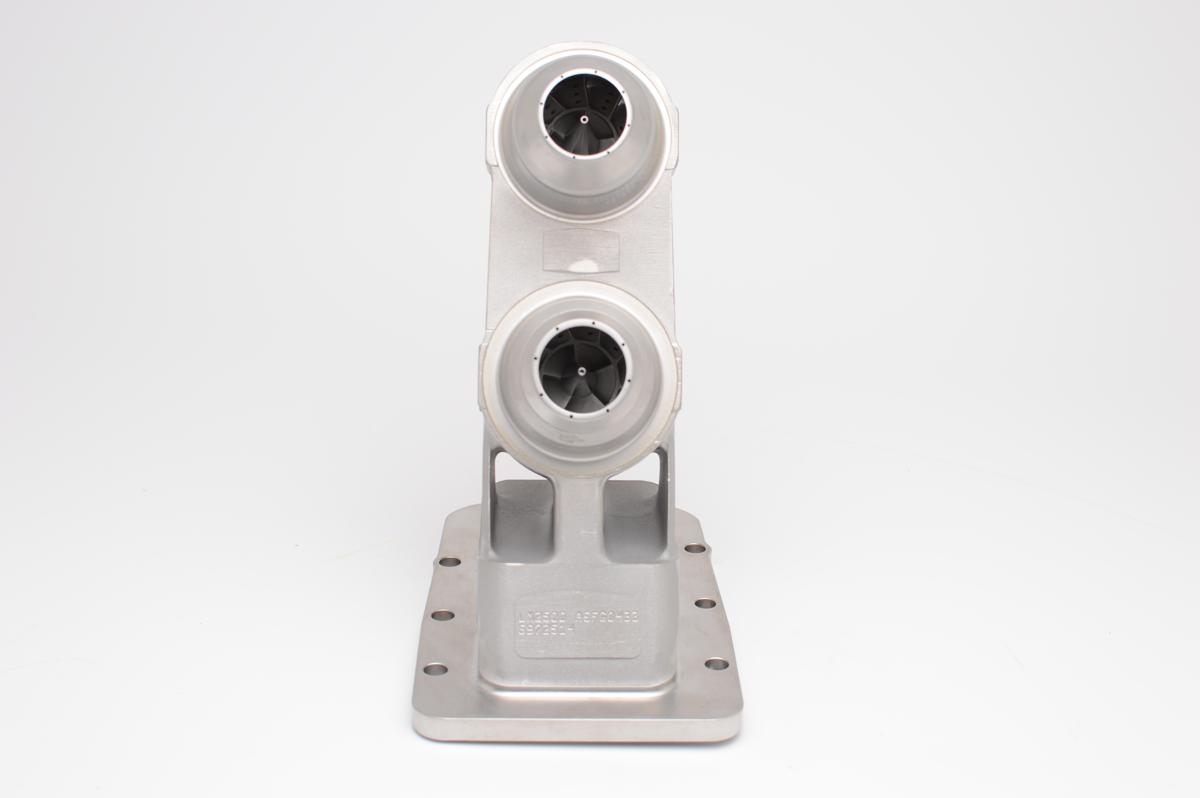

Dedicated tooling

for the TM2500

VBR designs and provides specialized tooling for TM2500 maintenance, including hot-section exchange toolkits. These tools are an improvement over the original GE tools. They are available for lease or purchase.

Maximize uptime for the TM2500

VBR has 25 years of experience working with TM2500 gas turbines in challenging environments such as offshore platforms, desert regions, and the Arctic.

Whether you are operating a TM2500 or one of its variants, we provide comprehensive services to ensure your turbine operates efficiently and reliably.

Field Services in remote regions

VBR has extensive experience working in Egypt, Africa and other distant regions. We provide field-based services to keep your TM2500 running smoothly, including troubleshooting and routine maintenance.

VBR provides on-site mechanical and control & instrumentation services for TM2500 engines.

Hot-Section Exchanges TM2500

There is an alternative to shipping your engine to an OEM-licensed overhaul depot. VBR Turbine Partners can perform a hot section exchange at your location.

This increases your influence over the repair process, reduces costs, and lowers turnaround times.

Gas Turbine

Relocation Services

VBR provides engineering and management support for the entire relocation process. We can manage it efficiently to minimize downtime and ensure optimal performance when the turbine is reinstalled.

Find the right part quickly

VBR stocks over 50,000 parts including critical parts for the TM2500. Feel free to contact us. We will address your concerns about lead time, OEM certification, and how fast you can have the part in your hands. We will ship your part on the same day.

Hot Section Repairs / Overhaul

VBR provides hot section overhaul & repair services for the TM2500 and its variants. We ensure high-quality service with OEM-approved parts and minimal downtime.

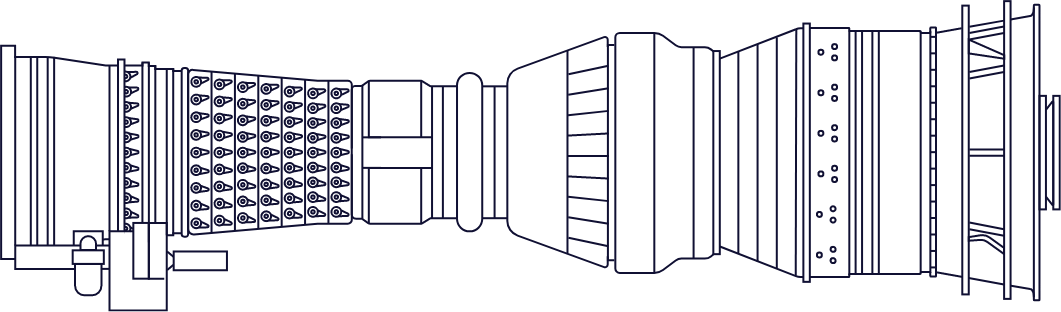

Familiarization Training LM 2500

This comprehensive 4-—to 5-day training covers the construction details, operational insights, and maintenance essentials of LM gas turbines and their auxiliaries.

Expect in-depth sessions covering these turbines’ inner workings and critical components.

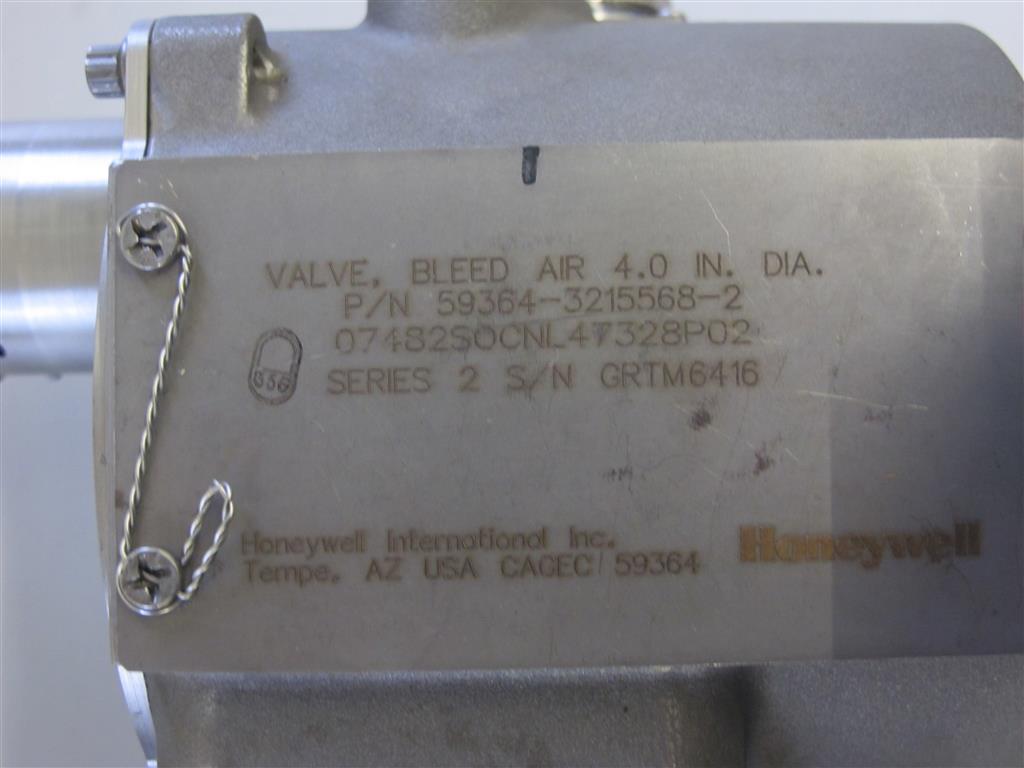

Meggitt Valves Overhaul

Many TM2500 DLE operators rely on Meggitt valves, including staging valves and other key components.

As an authorized Meggitt shop, we offer overhaul services for staging valves, PSOV valves, butterfly valves and fuel metering valves.

Maintenance Service Agreement (LTSA)

VBR prioritizes customers with Maintenance Service Agreements (LTSA). Our agreements can cover field services, spare parts, remote digital maintenance services, implementing service bulletins, and access to our helpdesk.

A Maintenance Service Agreement is the best way to reduce downtime and ensure uninterrupted business operations.