The benefits

- OEM recommended

- Longer operating time

- Longer operating time Longer shelf time

- No high voltage required

- No water or air cooling required

- No explosion proof conduit required

- More quality & safety certifications

- Available for all GE HD and some LM GT engine types

Learn more about reliable flame detection?

Flame detection & monitoring in GE Heavy Duty frame and LM aeroderivative gas turbines

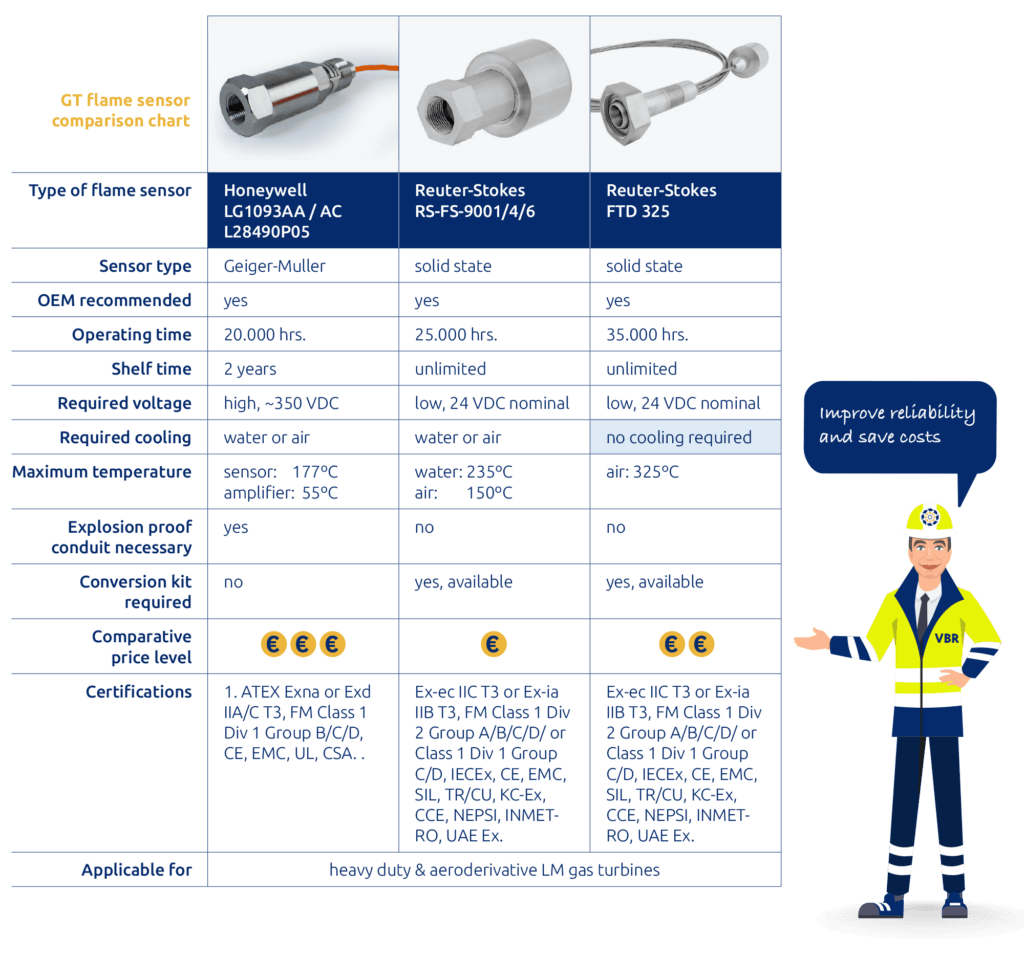

Many GE gas turbines currently in operation may still be equipped with Geiger-Muller based flame sensors. These LG1093AA and LG1093AC or L28490P05 flame sensors have restrictions in their lifetime expectancy and reliability. Reuter-Stokes solid state flame sensors like the RS-FS-9001 and the RS-FS-9009 or FTD325 have significant advantages over the classic Geiger-Muller alternatives, see the GT flame sensor comparison chart for detail

GT flame sensor comparison chart

Type of flame

sensor

Sensor type

OEM recommended

Operating time

Shelf time

Required voltage

Required cooling

Maximum

temperature

Explosion proof conduit necessary

Conversion kit

required

Comparative price

level

Certifications

Honeywell LG1093AA/AC L28490P05

Geiger-Muller

yes

20.000 hrs.

2 years

high, ~350 VDC

water or air

sensor: 177ºC amplifier:

55ºC

yes

no

![]()

![]()

![]()

1. ATEX Exna or Exd IIA/C T3, FM Class 1 Div 1 Group B/C/D, CE, EMC, UL, CSA.

Reuter-Stokes

RS-FS-9001/4/6

solid state

yes

25.000 hrs.

unlimited

low, 24 VDC nominal

water or air

water: 235ºC

air: 150ºC

no

yes, available

![]()

Ex-ec IIC T3 or Ex-ia IIB T3, FM Class 1 Div 2 Group A/B/C/D/ or Class 1 Div 1 Group C/D, IECEx, CE, EMC, SIL, TR/CU, KC-Ex, CCE, NEPSI, INMETRO, UAE Ex.

Reuter-Stokes

FTD 325

solid state

yes

35.000 hrs.

unlimited

low, 24 VDC nominal

no cooling required

air: 325ºC

no

yes, available

![]()

![]()

Ex-ec IIC T3 or Ex-ia IIB T3, FM Class 1 Div 2 Group A/B/C/D/ or Class 1 Div 1 Group C/D, IECEx, CE, EMC, SIL, TR/CU, KC-Ex, CCE, NEPSI, INMETRO, UAE Ex.

Applicable for

heavy duty & aeroderivative LM gas turbines

Flame Tracker Dry 325 (FTD325)

- Increased Safety (no water leaks)

- Reduced maintenance due to eliminating overheated sensor failures

- Higher recommended operating hours

- Enhanced availability/reliability

- No waterlines, simple outage maintenance

- Decreased risk of condensation

Learn more about reliable flame detection?

VBR provides cost-effective solutions.

Learn more about reliable flame detection?

VBR provides cost-effective solutions.