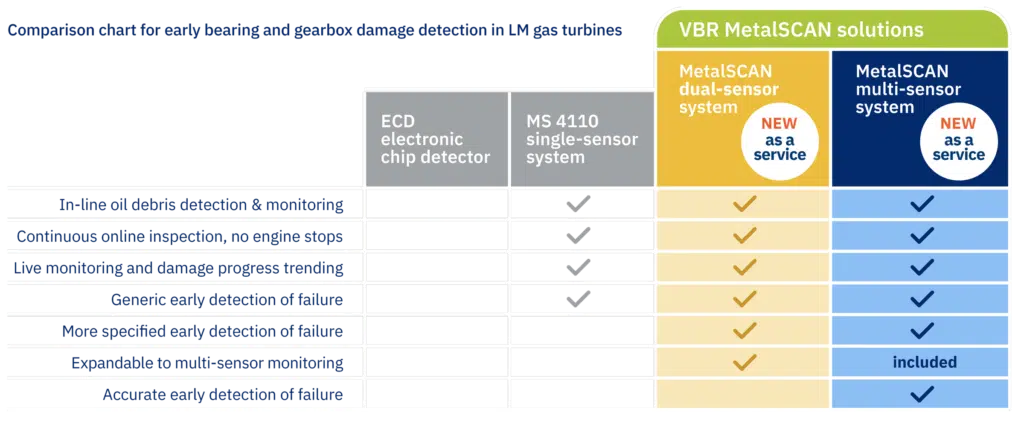

At VBR, we prioritize proactive solutions over-reactive measures. We’ve partnered with GasTops for their cutting-edge MetalSCAN MS4000 solution, providing REAL-TIME OIL DEBRIS MONITORING.

With MetalSCAN, you gain advanced knowledge of abnormal component wear, ensuring zero unplanned outages, lost revenue, or secondary damage. Bearing damage, a leading cause of unplanned events is effectively addressed with MetalSCAN, which offers real-time data on the critical component conditions and equipment health by analyzing 100% of wear debris in oil flow.

Real-time oil debris monitoring

Bearing damage is the leading cause of unplanned events. MetalSCAN MS4000 offers engine, turbine, and gearbox operators real-time data on critical component conditions and equipment health by detecting and analyzing 100% of wear debris in oil flow.

MetalSCAN MS4000 technology enables operators to maximize equipment availability, reduce risk, carry out predictive maintenance, extend overhaul intervals, predict component remaining life, and avoid secondary damage and costly equipment failures.

MetalSCAN enables real-time prognostics in condition-based maintenance (CBM) for critical oil-wetted components.

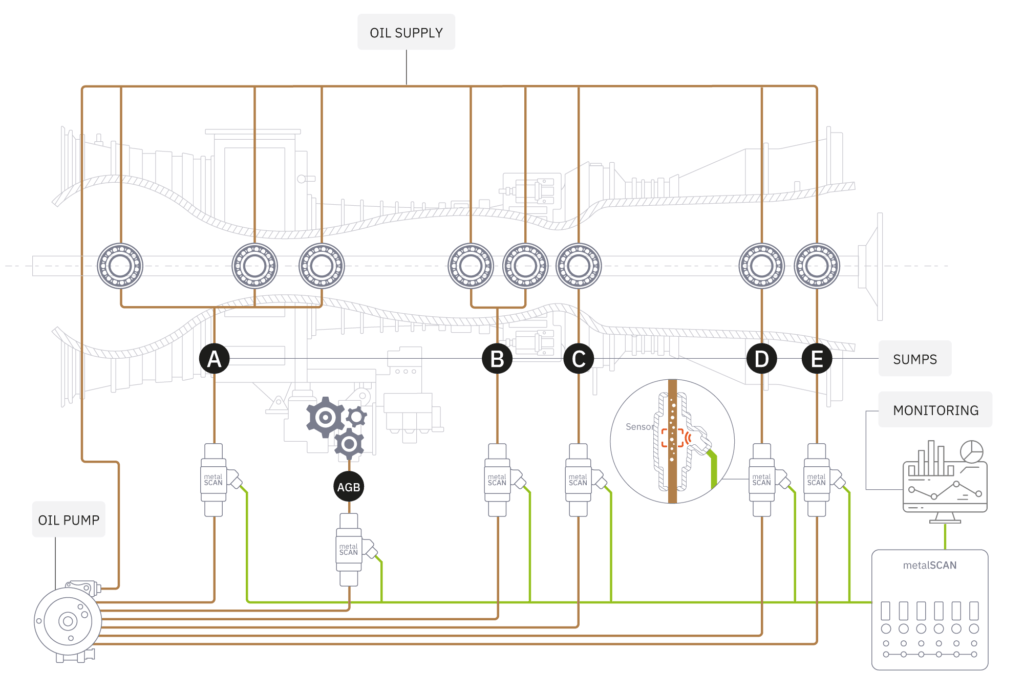

How MetalSCAN works

More than a particle counter, MetalSCAN is an online oil debris sensor that detects 100% of metal particles present in oil flow and compares damage progression to our proprietary statistical models.

This wear debris sensor detects failure modes for critical components: bearings, gears, seals, and blades, and identifies surface fatigue damage, building debris, and seal damage.

Using this information, MetalSCAN provides real-time indication of the severity and progression of damage.

This oil debris sensor gives the earliest warning that equipment will require maintenance and estimates Remaining Useful Life (RUL).

Simple solid state and reliable design

Gastops MetalSCAN has no moving parts. It has been designed for heavy industrial use and to withstand high temperatures year in and year out. MetalSCAN monitors lube oil debris at a particle level and is able to detect bearing damage in a very early stage. It uses a through-flow inductive sensor that is installed inline within the turbine lubrication oil system. The sensor is capable of detecting and categorizing ferrous and non-ferrous particles by size and type. MetalSCAN requires minimal maintenance and does not indicate ‘false positives’.

More insights? Read our MetalSCAN casestudy

Ask for a quote or further information : global@vbr-turbinepartners.com

VBR Turbine Partners is the authorized Gastops partner

VBR Turbine Partners are the exclusive and authorized distributors for metalSCAN. MetalSCAN is provided as a dedicated service for 24/7 monitoring of the gas turbine’s bearing condition.

Do you wish to minimize the risk of secondary damage in case of bearing failure?

VBR provides cost-effective solutions.